NISO, NIS, NISF

End suction centrifugal pumps

The NISO/NIS/NISF series pumps are cantilever/cantilever-monoblock single-stage pumps with horizontal shaft arrangement. The flow part is designed using the translation technologies of hydrodynamic modeling (CFD) and strength analysis by the finite element method.

• Power: 0.37 ~ 200 kW

• Head: 4 ~ 160 m

• Flow range: 3 ~ 1200 m³/h

• Temperature of pumped liquid: -15 ~ 110°C

Applications

• Water supply and water treatment

• Air conditioning systems

• Cooling and circulation systems

• Fire protection systems

• Irrigation systems

• Technological systems

Features and advantages

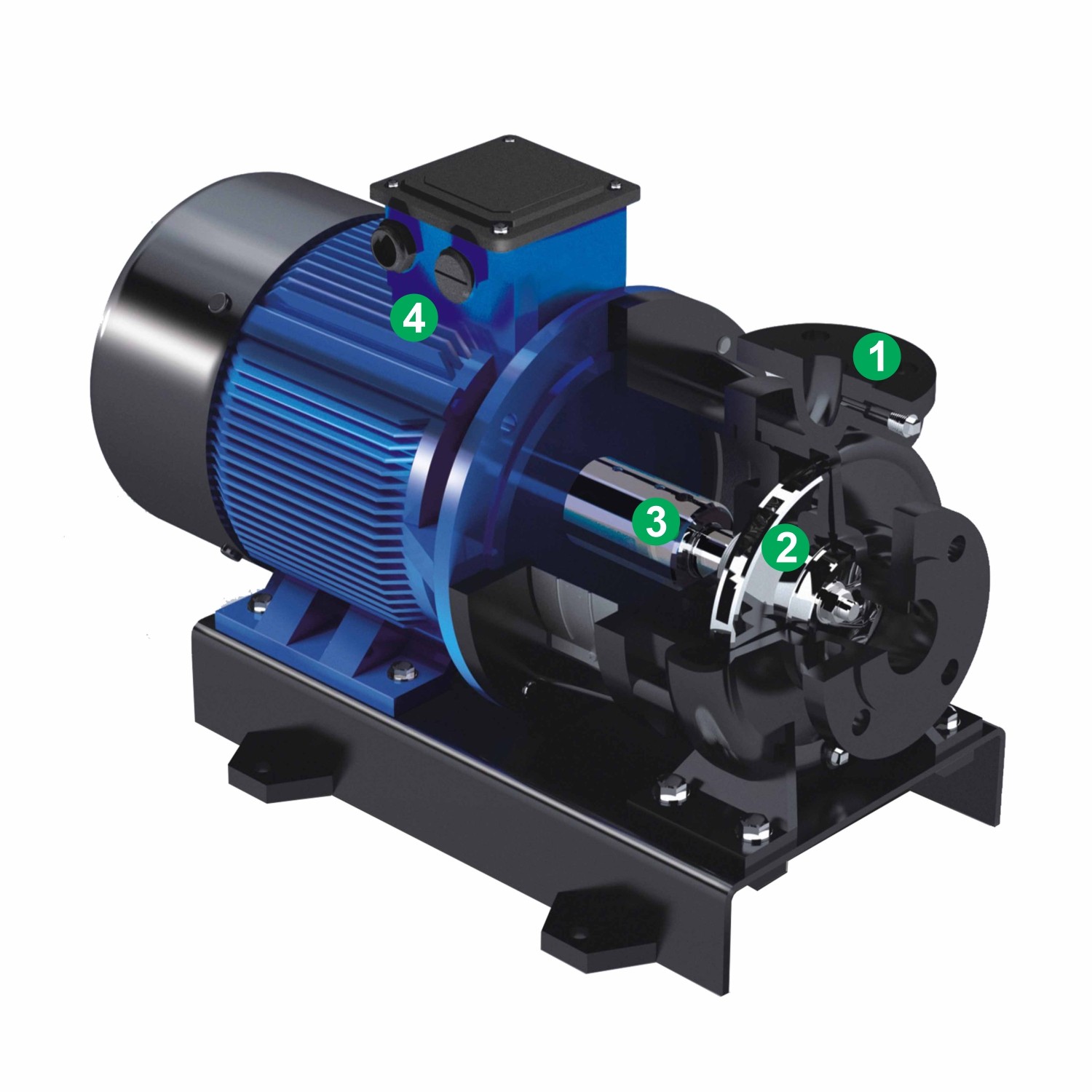

The pump units consist of two main parts (flow part and electric motor) and are mounted on a common frame base. The discharge branch of the pump part is radial, the suction branch is axial. Due to the technological design, the dismantling of the bearing unit with the shaft, seal unit, and impeller can be carried out without disconnecting the pump body from the pipeline system.

The pump units consist of two main parts (flow part and electric motor) and are mounted on a common frame base. The discharge branch of the pump part is radial, the suction branch is axial. Due to the technological design, the dismantling of the bearing unit with the shaft, seal unit, and impeller can be carried out without disconnecting the pump body from the pipeline system.

1.

The overall and connection dimensions of the pumps comply with ISO 2858. Flanges can be made of cast iron (according to ISO7005-1) or stainless steel (according to ISO7005-2)

2. The pump flow path is designed using modern methods of hydrodynamic modeling (CFD). The impellers are hydraulically unloaded from the axial force using special unloading holes, which increases the service life of the pump bearings. A mechanical seal is used as a seal for the flow path. The impellers also have an increased inlet diameter, which allows achieving the best NPSHR values.

3. NIS/NISF series pumps are monoblock: the shafts are connected using a keyed connection (the shaft of the pump part is concentrically mounted on the electric motor shaft). In NISO series pumps, the shafts are connected using an elastic coupling, which is protected by a protective casing for safety purposes.

4. Asynchronous electric motor, complies with IEC standards, mounting design B3 (NISO), B35 (NIS/NISF).

Working conditions

They are used to supply clean or slightly turbid water with pH=6 ~ 9 in stationary conditions, and other liquids similar to water in density, viscosity and chemical activity, containing solid inclusions up to 0.2 mm in size, the volume concentration of which does not exceed 0.1%, non-aggressive to the material of the pump flow part - cast iron.

• Temperature of pumped liquid: -15 ~ 110°C

• Maximum working pressure: 16 bar

• Maximum inlet pressure: 6 bar

Electric motor

• Energy efficiency class: IE2 (IE3 on request)

• Protection class: IP55

• Insulation class: F

• Standard voltage: 1x220V/3x220/380V/3x380V