NSC

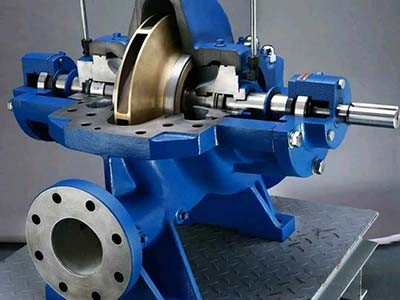

Single stage double suction split case pumps

The NSC series pump casing is axially split, allowing the entire rotor to be removed without moving the pipe or motor. High-head pumps have double volutes to reduce radial forces. Replaceable wear rings protect the casing at impeller clearance. Flanges are drilled to ISO, DIN, BS, or ANSI. Enclosed double suction impellers provide practically zero axial force. Each impeller is statically and dynamically balanced according to ISO1940. Vertical or horizontal, soft packing or mechanical seal, grease, or oil lubricated bearings on request.

• Head: 10 ~ 230 m

• Flow range: 50 ~ 20000 m³/h

• Speed: N 2900/1450/980/740/580rpm; 3500/1750/1180/890/710rpm

• Temperature of pumped liquid: -15 ~ 150°C

Applications

• Process: quench water, stripper bottoms, water circulation, cooling tower

• Pulp and paper: primary and secondary cleaner, filrate, mill water supply

• Primary metals: cooling water, quench and leaching

• Municipal: high lift, low lift, wash water, waste water, raw water

• Power generation: cooling tower, component cooling, service water

• Marine: bilge and ballast, cargo, cooling water, fire pump

• General: river water, brine, sea water, fire-fighting system, wate and sewage works

Features and advantages

The double suction pump enters the water from both sides, and the pump has good cavitation performance, high efficiency, and energy saving.

The utility model has the advantages of simple installation, convenient maintenance, and compact structure.

During maintenance, there is no need to disassemble the inlet and outlet pipes, open the pump cover, and the rotor can be taken out for maintenance.

Working conditions

Types of pumped liquid:

• Pure water or other liquid similar in physical and chemical properties

• Abrasive-containing liquids (sand, scale, etc.)

• Aggressive environment (desalinated, saline, sea water, etc.)

• High-temperature environment (water circulation in heating systems, all types of chemical liquids)

• Oil and oil products (in accordance with API 610 BB1)

• Maximum working pressire 5 MPa

• Content of foreign inclusions: ≤4%

Electric motor

Depending on customer requirements and power, the pump unit can be equipped with a high-voltage or low-voltage electric motor.

Low voltage electric motor High voltage electric motor

• Voltage 60Hz 380V • Voltage 60Hz 6000V, 10000V

• Insulation class: F, H • Insulation class: F, H

• Protection class: IP54, IP55 • Protection class: IP23, IP54, IP55

• Number of poles: 2, 4, 6, 8, 10 • Number of poles: 2, 4, 6, 8, 10, 12

• Energy efficiency class: IE2, IE3 • Cooling method: IC01, IC81W, IC611